RISK – Equipment failure

If damage or a defect is found, stop using the machine, tag it out of service, isolate the machine from use and report it to your Supervisor. For low level lifts, complete a pre-lift start card.

A function test will also be required for cranes.

Lifting gear must be visually inspected, marked with the appropriate colour code (using the RGBY system) and confirmed fit for purpose prior to being put into service.

Visual inspections of all lifting equipment must be conducted prior to each use to ensure fit for purpose.

|

Quarter |

Colour |

|

January – March |

Red |

|

April – June |

Green |

|

July – September |

Blue |

|

October - December |

Yellow |

All equipment deemed unsuitable for use (i.e. faulty or defective) must be tagged out of service and quarantined to prevent its reuse.

All lifting equipment (including crane workboxes) must be inspected on a quarterly basis by an experienced Intermediate Rigger.

12 monthly inspections must be conducted by an external third party. Annual inspections may need to be conducted more frequently depending on the environment, design and usage of the lifting equipment.

All rigging and lifting equipment must be suitably stored to prevent loss of structural integrity.

Wire Ropes and slings

If any of the following are identified, immediately tag out of service:

- Signs of stretching

- Broken wires (>10% or as per manufacturer instructions)

- Kinking, crushing or core collapse

- Corrosion

- Distortion adjacent to the termination

- Damage to the ferrule on the ferrule

- Loose / deformed thimbles

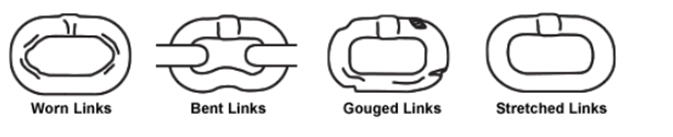

Chains and chain slings

If any of the following are identified, immediately tag out of service:

- Worn or corroded

- Deformed, chipped, nicked or cracked

- Master links and coupling damage

- Locked links

- Bent links

- Stretching

- Weld splatter

- Indentations or gouged links

Peerlesschains.com.au

Synthetic Slings

If any of the following are identified, immediately tag out of service:

- Frayed

- Abrasion

- Acid / caustic burns

- Melting of charring

- Snags, punctures, tears or cuts

- Worn or broken stitching

- Stretched

- Knots

Mazzella Companies. Lifting and rigging Learning Centre

Lifting equipment that carries material, such as bins and lifting cages must be engineer designed, certified and display the Working Load Limit (WLL) or Safe Working Load (SWL).

Related GMRs

Related Procedures / Forms